When a business is looking for a plastic molding manufacturer, they look for one that offers more than just products and services. They want to find a company that provides them with a one-stop-shop experience. What does this mean? It means that manufacturers who offer services like prototype development, design consultation, engineering, tooling design, and mold making are more appealing than those who only offer products.

So why is this the case?

It’s simple really. When you have a tight time frame or need some specific custom work done, you want to work with one manufacturer instead of several. This way, you get everything you need in one location and don’t have to worry about managing multiple vendors and suppliers.

Moreover, by working with just one company, you’ll save yourself valuable time and energy. You will also have access to all of the detailed information about each step of the process, so you can rest assured that everything will go smoothly from start to finish.

Here is a brief insight into the advantages of going with a one-stop-shop for your plastics manufacturing.

Benefits of Having a One-stop Shop in Plastics Manufacturing

Increased Efficiency

By bringing together a variety of vendors and manufacturers in the same place, it streamlines the manufacturing process hence eliminating errors in the process. This ensures your custom product is created efficiently.

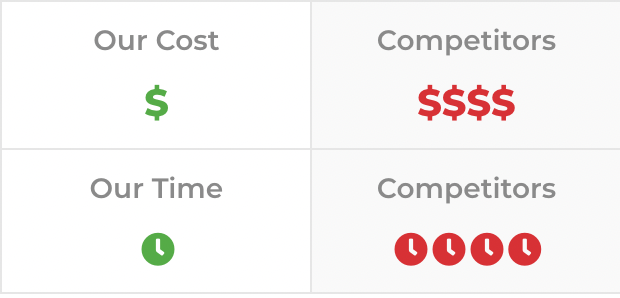

Affordable Rates

With a one-stop-shop for plastic manufacturing, you can now access bigger and more diverse supplying resources. There is no need to worry about the price difference between manufacturers and retailers anymore.

Maintains Product Quality

A centralized in-house quality control system ensures that your products are manufactured according to industry standards. This eliminates the risks and costs associated with inconsistent goods.

Faster Delivery Times

The ability to manufacture plastic parts for different industries and applications in-house, and on your schedule, means shorter delivery times, and greater control over quality and cost. No need to search the marketplace to find the right manufacturer.

One Source for Multiple Services

You no longer have to spend time searching different websites and dealing with several companies for your packaging supplies. These companies offer everything under one roof so that you don’t have to deal with multiple sources and contracts.

Customization

Customers look for companies that offer customized solutions that can catch their attention. A one-stop shop will help you design your own custom packaging as well. They can help you choose the size, shape, and color of your product packaging to make your product stand out.

Inventory Management

Working with a single supplier means you save time when it comes to ordering your products or creating prototypes. You will know who to contact if you need new parts, and there will be no guessing games about how long it will take for those parts to arrive. This also makes it easier for you to manage your inventory because you won’t have to worry about tracking down different suppliers for each component.

Quick Solutions

Having all of your needs addressed by one service provider can make emergencies much easier to handle. If a complication does arise, the team can help you resolve the issue without looking for alternative providers. This means you do not have to waste time and money switching from one company to another to get your needs handled.

We Do It All

Trying to handle multiple suppliers at the same time can be very stressful and time-consuming. It’s much more efficient to work with a single entity that can provide all the products you need in one go. Our company will help you save money, ensure product quality, and deliver them on time.

With state-of-the-art equipment, and our talented team of experienced engineers as well as plastic specialists, we can handle even your most complex project.

Grand Canyon Plastics is here for you, ready to produce your next project on time and within budget. Ready to get started? Get in touch.